Let's have a simple opening statement

Do you know the specific structure of the nozzle of Xikang pump? Do you want to have a deeper understanding of the maintenance plan for Xikang pump nozzles? Don't worry, the editor will share it with you now!!

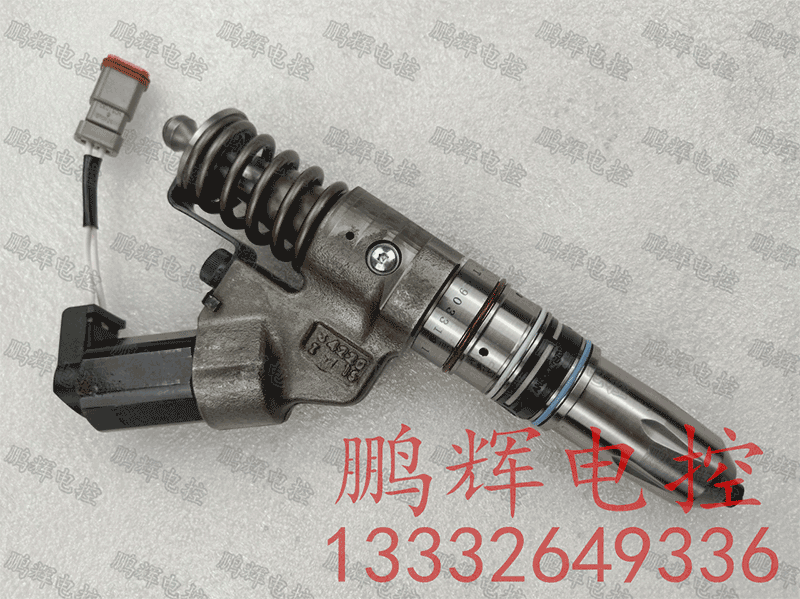

Structural Decomposition of Xikang M11

The above is a detailed anatomical diagram of the Xikang M11 fuel injector, some of which are prone to damage, such as the fuel injector parts, fuel injector top rod, fuel injector spring, solenoid valve armature assembly, and measuring plunger.

I have these vulnerable parts for sale here!! In addition, there are also major repair kits and minor repair kits, both of which are commonly used for replacing spare parts.

The overhaul package includes various sizes of O-rings, bias springs, measuring check valves, washers, plug screws, nozzle springs, nozzle top rods, inlet filters, nozzle connecting wires, etc.

The small repair kit includes O-rings of various sizes.

Without further ado, I believe everyone is more concerned about the maintenance methods of the fuel injector. Below, the editor will introduce to you the impact of various components of the Xikang M11 being damaged!

The impact of component damage

1. Wear of the timing plunger and housing can cause diesel leakage into the oil pan and increase in engine oil

2. The measuring column is worn when inserted into the oil hole - the oil volume increases, black smoke is emitted, fuel consumption increases, and idle speed is unstable.

3. Wear and tear of oil nozzle components - the nozzle holes become larger, the fuel volume increases, resulting in black smoke from exhaust, sinking of the oil nozzle needle, and easy sticking of the oil nozzle.

4. Damaged filter screen - can cause blockage of the oil inlet.

5. If the pressure relief valve body spring breaks or gets stuck, it will cause excessive oil return. If all of it gets stuck, it will cause difficulty in starting.

6. Sinking around the center hole of the nozzle spring guide sleeve - excessive fuel injection.

7. The center hole of the armature seat is worn, and the center end face is worn - the stroke of the armature increases, the oil volume increases, black smoke is emitted, fuel consumption increases, and idle speed is unstable.

8. The end face of the armature rod is worn or loose with the armature disk - emitting black smoke, increasing fuel consumption, and unstable idle speed. The armature rod is broken, and the fuel injector cannot work.

9. The armature rod is broken - the fuel injector cannot work.

10. Wear on the contact surface between the upper and lower sealing rings - abnormal fuel injection quantity and nozzle operation.

11. Wear of the nut of the armature rod and the conical surface of the lower sealing ring - poor sealing.

12. Wear of nozzle top rod - The opening pressure of the nozzle decreases, making it easy for the nozzle to get stuck, increasing fuel consumption, and emitting black smoke from the exhaust.

13. Unbalanced spring fracture - Inaccurate fuel injection timing, causing easy knocking and even failure to work.

14. Faulty nozzle spring - The opening pressure of the nozzle decreases, making it easy for the nozzle to get stuck, increasing fuel consumption, and emitting black or white smoke from the exhaust.

When measuring the resistance of an electromagnetic valve, first check if there is any erosion or damage on the end face, and then measure the resistance.

When the fuel injector is damaged or not functioning properly, you can carefully inspect the damaged components based on the impact of each component damage, and find the parts that need to be replaced for replacement.

In addition to the repair plan, the accessories, assemblies, and tool equipment in the picture are also provided by the editor!!

Contact information:

Chen Gaowei: 13332649336

Tang Ping: 13532849238